The Micro IRHD DX-13 hardness tester is ideal for measuring the hardness of thermoplastic and vulcanised rubber specimens, such as O-rings, cables, rubber hoses and medical items.

Particularly recommended for samples of small size and thickness, usually less than 6 mm.

Integrated into the company’s control-production system, the Micro IRHD hardness tester is of great help for:

Discover all the technical details of DX-13

The DX-13 software was developed and put into operation by our own research and development department to ensure maximum attention and precision during IRHD hardness testing activities.

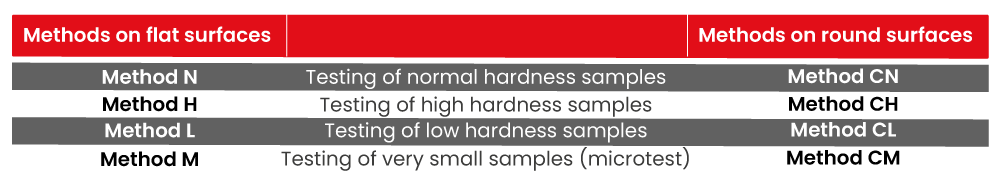

In developing it, we made sure that it could accommodate all the 8 scales provided for in the main international reference standard, the ISO 48-2.

To make the change of scale faster and safer, the DX-13 software is self-guided: by simply selecting the scale to be used on the display, the force settings are automatically adjusted and the user is guided in the selection and installation of the correct reference indenter.

The proprietary IRHD software can be linked with the company’s ERP and MES to ensure continuous data interchange.

The returned reference values are precise and accurate, tailored to your needs. With its many functions, it gives, amongst others, the possibility to:

create personal hierarchical profiles for access to the IRHD hardness tester that store and retrieve recorded work sessions for the individual user, with different levels of authority depending on the type of user (admin, user etc.)

preset scales, tolerances and other IRHD test cycle setting parameters

create, edit and customise statistics, histograms, diagrams and standard deviations with your own company and job data

We are the only company on the market to have integrated in our IRHD-Micro and Macro hardness test cycle a system that guarantees all the benefits connected with the insensitivity of the test to the possible failure of the test specimen. This system allows, in fact, the stabilisation of the applied force during each stage of the test, ensuring a higher level of result repeatability.

Thanks to the motorised 50 mm stroke, the test cycle is simplified and improved through increased reproducibility.

Forces are applied electronically by the load cell with Closed Loop control system (frequency of 1000 pulses per second). This guarantees extreme accuracy, eliminating the problems associated with older generation IRHD hardness testers, which relied on a calibrated mass measuring system, more commonly known as “deadweight” testers.

Discover all the technical details of DX-13